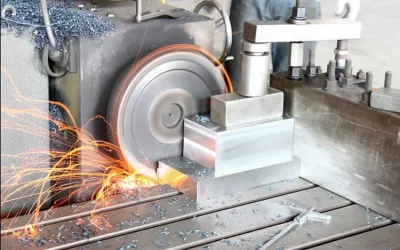

S136 for mold tooling

S136 is a high-quality material that offers a number of benefits for mold tooling applications. Its combination of corrosion resistance, wear resistance, machinability, and thermal conductivity make it a popular choice for applications where high performance is required. However, it’s important to note that S136 can be a more expensive option than other materials, so it’s important to consider the specific requirements of the application when selecting a material for mold tooling.

PA for CNC Machining Components

PA for CNC machining components is a versatile material that offers numerous benefits, including high strength, wear resistance, and chemical resistance. Its wide range of applications in various industries makes it an ideal choice for producing durable, high-performance parts. By selecting the right PA material and following best practicesfor CNC machining, you can ensure successful outcomes for your projects.

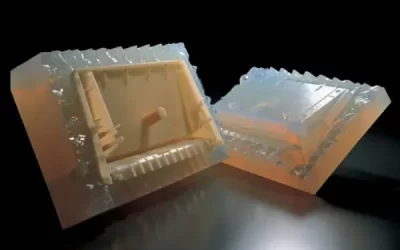

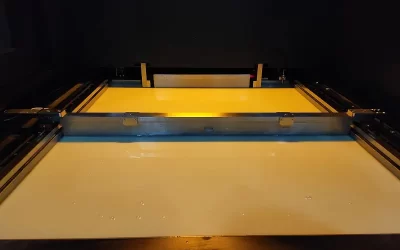

Silicone for vacuum casting is a popular choice

Silicone is a popular material for vacuum casting due to its unique properties, including flexibility, low shrinkage, high tear strength, and good chemical resistance. It is used in a wide range of industries and applications, such as medical devices, automotive parts, consumer products, and prototyping. However, it also has some potential drawbacks, such as higher cost and longer curing time compared to other materials. Understanding the properties and limitations of silicone is crucial for selecting the appropriate material for a specific application and optimizing the vacuum casting process to produce high-quality parts and components.

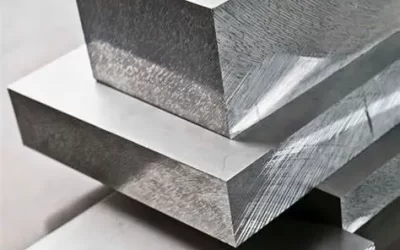

Aluminum 6063 T6 for cnc machining parts

Aluminum 6063 T6 is a versatile material that offers numerous benefits for CNC machining parts. Its high strength-to-weight ratio, excellent machinability, durability, and corrosion resistance make it suitable for various industries, including aerospace, automotive, electronics, and marine. Understanding its chemical composition and mechanical properties is crucial for selecting the appropriate material for a particular application. Using CNC machining for Aluminum 6063 T6 offers precision, accuracy, flexibility, customization, and aesthetics. Its application fields are diverse and include aerospace, automotive, electronics, architectural, marine, and medical industries.

CNC Machining Aluminum alloy 7075 for Custom Manufacturing

Aluminum alloy 7075 is a high-strength material commonly used in the aerospace, automotive, and defense industries due to its excellent mechanical properties. It is a heat-treatable alloy, which means that its properties can be enhanced by heat treatment. 7075 alloy is also known for its resistance to stress corrosion cracking, making it a popular choice for applications where the material will be subjected to high stress environments.

ABS-like photosensitive resin used in SLA 3D printing

ABS-like photosensitive resin is a type of material that is commonly used in SLA 3D printing due to its properties, which mimic those of ABS plastic. This resin is a liquid polymer that is cured by a light source, such as a laser or a UV lamp, to create solid parts layer by layer. ABS-like photosensitive resin is known for its high strength, durability, heat resistance, chemical resistance, and smooth surface finish, making it suitable for a wide range of applications.

Polyethylene (PE) is a widely used material for cnc machining

Polyethylene is a thermoplastic polymer that is lightweight, durable, and resistant to moisture, chemicals, and impact. It is widely used in various industries, including aerospace, automotive, medical, and consumer products. CNC machining of polyethylene involves cutting, shaping, and forming the material into various shapes and forms.

PU applied in vacuum casting for small batch production

PU (polyurethane) is a popular material used in vacuum casting for small batch production. It offers high accuracy and precision, cost-effectiveness, fast turnaround time, customization options, and versatility. PU material is ideal for creating parts or prototypes with complex geometries and tight tolerances, and it can be used in various industries such as automotive, aerospace, medical, and consumer electronics.

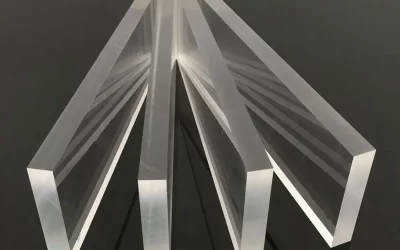

PMMA used in CNC machining

PMMA, also known as acrylic or plexiglass, is a transparent thermoplastic material that is commonly used in CNC machining. It has excellent optical clarity, high tensile strength, chemical resistance, and is easy to machine. PMMA material is ideal for creating complex shapes and designs, making it a popular choice for various applications such as display cases, signs, lenses, lighting fixtures, and medical devices. Its unique combination of properties makes it a versatile material that can be used in many industries.