PMMA’s unique properties and versatility make it a material of choice across various industries, including automotive, aerospace, electronics, architecture, and healthcare. PMMA enables innovation by offering design flexibility and customization options that were previously unachievable. Its exceptional transparency, lightweight nature, mechanical strength, UV resistance, and thermal properties contribute to enhanced performance in a wide range of applications.

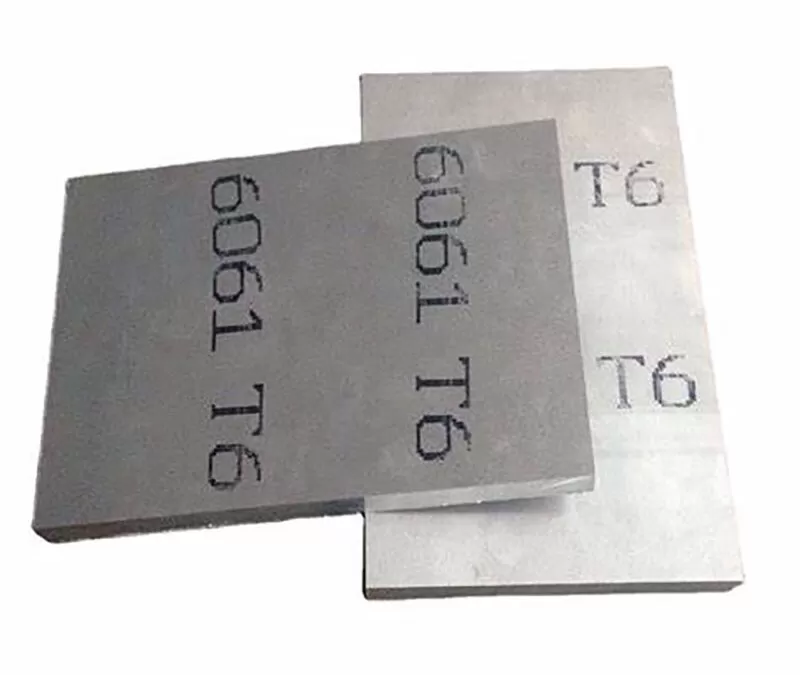

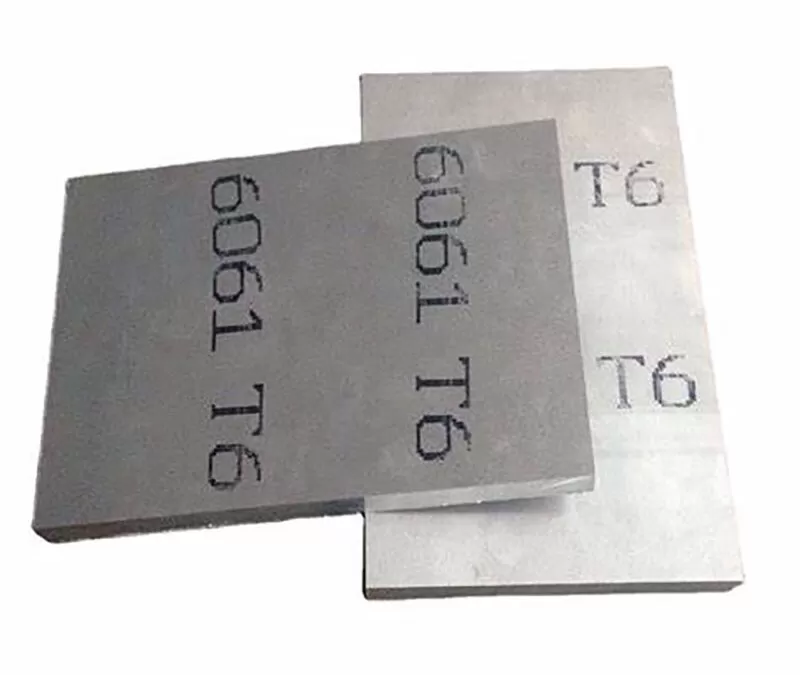

Aluminum 6061 offers a winning combination of strength, machinability, and versatility, making it an ideal choice for CNC machining components. Embracing this exceptional material empowers manufacturers to push the boundaries of innovation, enhance performance, and deliver high-quality products across diverse industries. Unlock the potential of Aluminum 6061 and witness the transformative impact it can have on your CNC machining projects.

PMMA (polymethyl methacrylate) plays a crucial role in custom LED lighting manufacturing. It is utilized in the form of lenses, diffusers, covers, and light guides to enhance the performance, aesthetics, and functionality of LED lighting fixtures. PMMA’s optical clarity, light transmission efficiency, and design flexibility make it an ideal choice for achieving uniform illumination, controlling light distribution, and protecting lighting systems.

PTFE is a type of synthetic fluoropolymer plastic that is known for its unique combination of properties. It is made of molecules that consist of carbon and fluorine atoms, which are arranged in a repeating pattern. PTFE is a high-performance plastic that is used in various applications due to its excellent resistance to heat, chemicals, and moisture.

Aluminum 2017 is an excellent material for CNC machining due to its unique combination of properties, including high strength, excellent machinability, and resistance to corrosion. The material is commonly used in several industries, including aerospace, automotive, defense, and electronics, to produce high-quality and precise parts and products.

Selecting the right mold tooling material is crucial for achieving high-quality products and maximizing production efficiency. With so many options available, it can be challenging to determine which material is best suited for your specific application. In this guide, engineers from M2 Prototype will conduct a comprehensive comparison of common mold tooling materials, sharing some knowledge to help selecting the best mold tooling material for your needs.

High-strength vacuum casting resin is a versatile and reliable material that finds applications in various industries. By using high-strength vacuum casting resin, manufacturers can create parts that are strong, durable, and resistant to impact, ensuring the safety and reliability of their products.

This comprehensive guide aims to provide a detailed overview of the world of metal 3D printing materials. It covers the various metal 3D printing technologies, including powder bed fusion, directed energy deposition, binder jetting, and metal material extrusion. The guide also delves into the most common metal 3D printing materials, such as aluminum alloys, titanium alloys, stainless steel, tool steel, cobalt-chrome alloys, and nickel-based super alloys.

Sainless steel CNC machining offers several benefits for industrial applications, including durability, strength, and customization options. Various industries, such as aerospace, automotive, and medical devices, use stainless steel CNC machining to produce high-quality parts.

Manufacturers can achieve high-quality precision components in brass CNC machining by implementing best practices and leveraging the benefits of the process. By staying informed about the latest trends and technologies, manufacturers can continue to improve their production processes and meet the demands of their customers.