3D Printing Service

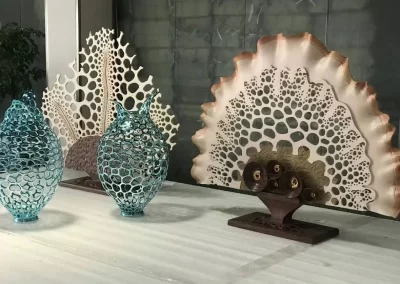

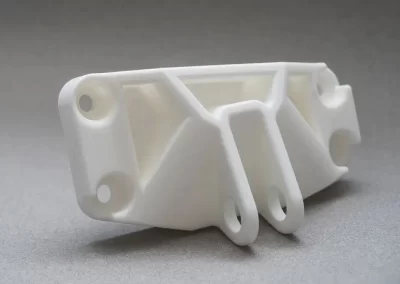

SLA 3D Printing Service

M2 SLA 3d printing capabilities

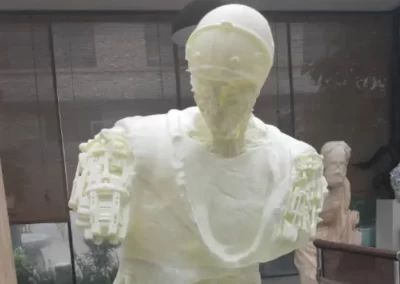

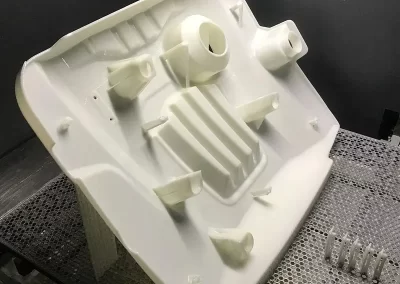

M2 always runs state-of-art 3d printers and executs tight inspection standards to take accuracy and quality as its priority. With our SLA 3D printing service, you can create amazing products with the confidence that your products will be accurate, consistent, and of the highest quality. A brief info about M2 sla 3d printing capabilities.

- Tolerance: ± 0.15%, with a lower limit of ± 0.01 mm.

- Max. build size: 800 x 800 x 450 mm.

- Layer height: 50-100 μm.

- Min. wall thickness: 1.0 mm.

- Lead time: normally 5 business days.

Benefits of M2 SLA 3d printing service.

- More complex parts can be easily handled efficiently.

- Compared to CNC machining, it is very material saving, results to cost saving.

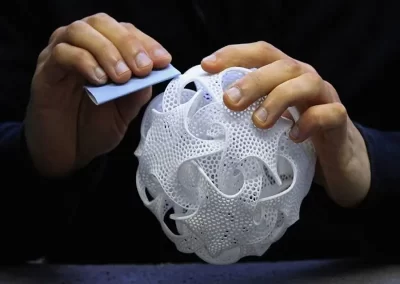

- Micro features and intricate details can be printed.

- Wide choices of surface finishing treatment.

- Quicker and efficient production time.

- Flexible and customizable, allowing for designs to be changed as needed during the production.

Materials for SLA 3d printing

Standard resin is our versatile material widely used for 3D printed consumer products, small components and prototypes due to its benefits such as fast curing, chemical and environmental resistance, low shrinkage and excellent surface finishing.

Clear resin is particularly suitable for producing high detail parts which require a transparent material or which need to mimic glass.

Tough resin is designed to produce parts which are thicker, tougher and more impact resistant than standard materials. It is ideal for producing functional parts which may be subjected to further machining, sandblasting and painting.

Durable resin is designed for applications that require extra strength and flexibility as well as resistance to chemical and environmental conditions. It is capable of withstanding extreme temperatures and has a range of benefits such as UV and chemical resistance, low shrinkage and abrasion resistance.

Heat resistant resin is specially designed for parts with complex geometries that need to withstand long exposure to temperatures up to 180°C. It is also capable of resisting shock, chemicals, electricity and weather.

Request a rapid prototype?

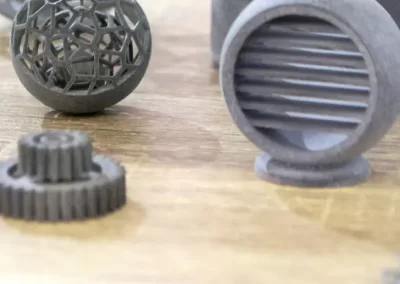

SLS 3D Printing Service

M2 SLS 3d printing capabilities

M2 SLS 3D printing service offers a cost-effective and highly customizable solution for product prototyping and manufacturing, enabling businesses to create low-volume production parts with minimal lead time. Our SLS technology allows for the production of complex and intricate shapes and geometries, enabling a more precise customization of products than traditional 3D printing methods. We use the latest materials and technologies to ensure that your customized manufacturing parts are of the highest quality and meet the most stringent standards. Below is a brief info about M2 sls 3d printing capabilities.

- Tolerance: ±0.3%, with a lower limit of ±0.3 mm.

- Max. build size: 420 * 500 * 420 mm.

- Layer height: 100 μm.

- Min. wall thickness: 1.0 mm.

- Lead time: normally 5 business days.

SLS 3D printing services by M2 offer rapid product-development capabilities and reliable production results. With our services, designers can quickly generate production ready parts for a variety of applications.

SLS 3d printing materials

Nylon 12 (PA 12) is a strong and durable 3D printing material that provides a great balance of performance, speed, and affordability. This material is often used for applications where parts require flexibility, strength, and good chemical resistance. It can be used to print both small and large parts, with a wide range of layer heights and thicknesses, and can handle a variety of shapes and geometries.

Glass-filled Nylon is a high-performance 3D printing material that adds strength and durability to 3D printed parts. Its abrasion resistance, strength and heat deflection temperature capabilities make it ideal for engineering applications. It has excellent mechanical and thermal properties and can be used to produce parts with a smooth finish and clean edges. Its higher glass fill also makes it more wear and tear resistant and increases its impact resistance, making it great for making parts that need to handle higher stress.

Other options of SLS 3d printing materials: FS3300PA、FS330GF、FS3400CF、FS3250MF、PA6.

Surface finishing process

Our surface finishing service ensures that your SLS 3D printing materials are ready for use in a range of applications. Experienced technicians in M2 use some of the most advanced and precise methods to give your SLS 3d printed components the smooth, clean surface required for functional or decorative purposes. The surface finishing process includes a number of steps that can be tailored to your specific needs.

- Carefully inspect the surface of the printed part for any imperfections, such as bumps or irregularities.

- Use several methods, such as sanding and chemical treatments, to smooth out and clean the surface.

- Choose from a range of aesthetic options such as painting, polishing or adding texturing or colours.

- Apply a protective clear-coat layer to protect the surface from scratches and damage, making sure your 3D printed products meet your desired quality standards.

More options please check our surface finishing page.

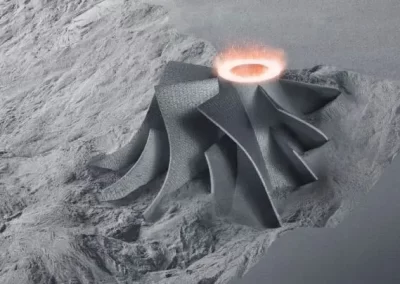

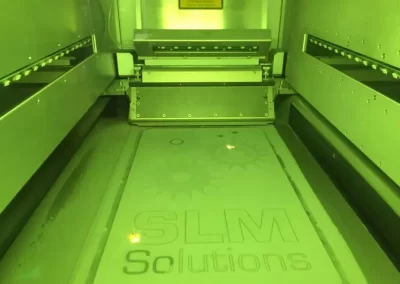

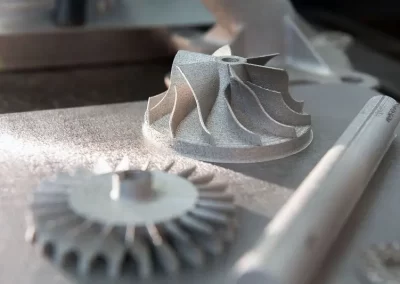

SLM 3D Printing Service

SLM advantags & applicaitons

SLM 3D Printing services are a revolutionary development in the world of manufacturing and prototyping. Selective Laser Melting is an additive manufacturing process whereby metal powders are selectively melted layer by layer to create complex 3 dimensional parts and components. With our SLM 3D printing services, virtually any shape and geometry can be machined with ease, offering a high level of freedom for designers and product engineers. SLM 3D printing is perfect for creating prototypes, producing low-volume parts, and achieving complex geometries that don’t necessarily have to be produced with traditional tooling. This makes it an incredibly versatile process. It is also highly accurate and offers excellent repeatability, making it extremely reliable for producing high-quality components. Whether you need to produce low-cost single parts, large batch production runs, intricate prototypes, or complex tooling parts, SLM 3D printing services can meet your production needs.

SLM 3d printing materials

M2 provides below metal powder materials for your SLM 3d printing of your on demand prototypes.

AlSi10Mg is an aluminum alloy comprised of 10% silicon and 5% magnesium, with trace amounts of iron. It is known for its excellent thermal properties. It also offers excellent mechanical properties, including good tensile strength and fatigue resistance, making it an ideal choice for many applications, especially those involving high-temperature requirement. It is an excellent option for applications such as aircraft components, electrical and thermoelectric components, automotive parts, telecommunications parts, and medical implants.

Stainless steel 316L exhibits excellent resistance to high temperatures, fatigue, and stress corrosion cracking, making it a great choice for some SLM 3D printing applications, both in short- and long-term applications.

Other optional SLM 3d printing materials: 17-4PH, IN625, IN718, Ti64, Cu90Sn10, 420.

Surface finishing options

In order to improve the appearance, surface roughness and mechanical properties of SLM 3d printed parts, post surface finish processing is a important issue to be solved.

The types of surface finishing that can be applied to SLM 3D printed products is extensive. It includes options such as buffing, deburring, filling, and plating. The use of these services is necessary for the successful completion of the production process and for the end-user’s satisfaction.

No matter what your needs are, surface finishing services for SLM 3D printed parts can help you reach the desired results. With these specialized services, one can easily achieve a perfect, smooth finish and improve the appearance of the part. It is important to work with a professional surface finishing company to ensure the best outcome. M2 will provide you with professional and experienced personnel who are highly trained in the use of the various processes associated with SLM 3D printing.